Predictivemaintenence &AI

Predictive maintenance & artificial intelligence: modern approaches for smooth production

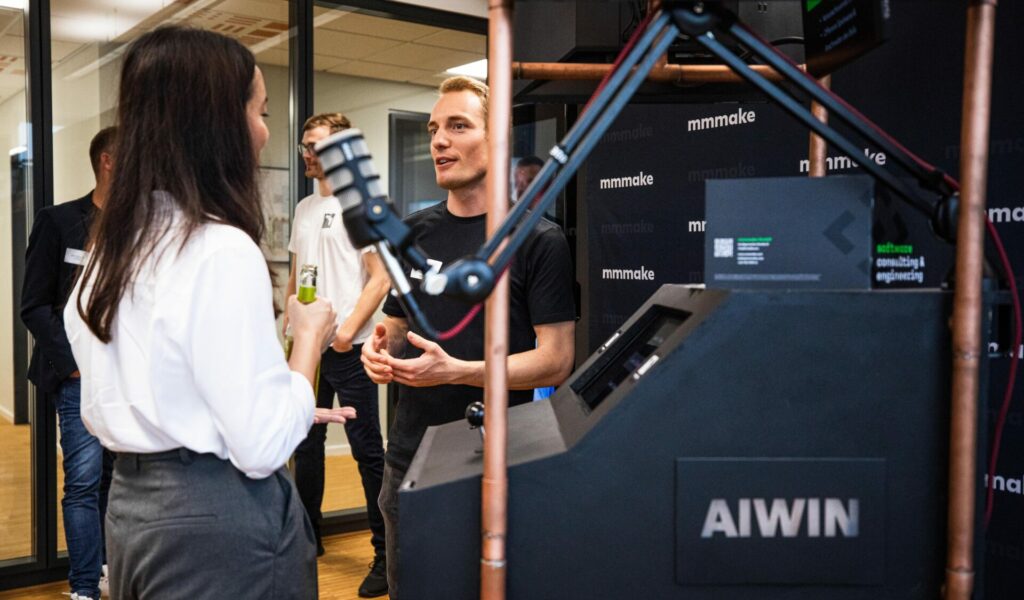

The combination of AI and predictive maintenance makes it possible to work more efficiently by reducing machine downtime to a minimum. This frees up resources for other tasks and allows production to continue uninterrupted.

React instead of act

Unplanned machine downtime creates gaps in the daily schedule that negatively impact employee and customer satisfaction. This unexpected downtime and the associated costs lead to lost productivity, complicated planning and inefficient allocation of resources – and in the worst case, lost customers.

Always be one step ahead

Our AI experts work with you to develop a customized solution for your system landscape and deploy AI-powered predictive maintenance measures to achieve greater reliability and efficiency. And, by using sensors, technicians:inside can monitor vibration, oiling, heating, metal integrity and general wear for a variety of production systems in real time.